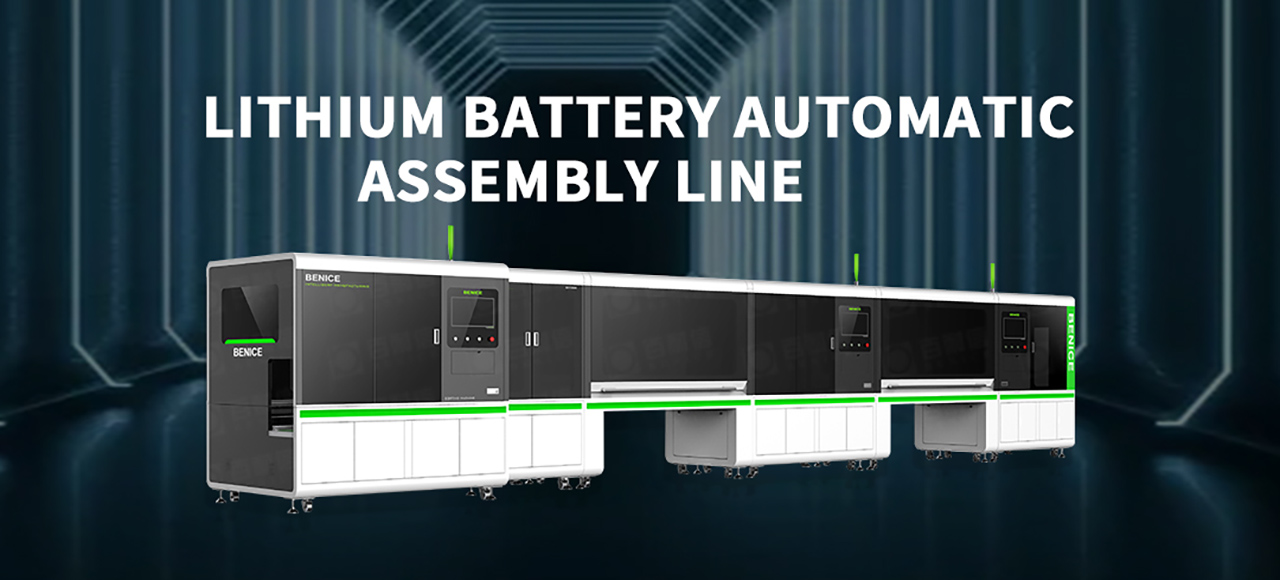

Professional China Internal Resistance Tester Of Battery - Lithium battery assembly automation production line – Benice

Professional China Internal Resistance Tester Of Battery - Lithium battery assembly automation production line – Benice Detail:

Product Features

The assembly of motor products is generally divided into the following categories: automatic assembly, semi-automatic assembly, and manual assembly. Among them, the manual assembly efficiency of the motor is low, and the semi-automatic assembly is a combination of machinery and manual work. Machine assembly is done by hand, and fully automatic assembly requires a high degree of standardization of product parts, but it can achieve fully automatic production, without manual, intelligent assembly, and we will according to the processing technology of the motor products and the speed of the production line required by customers, Let’s consider the assembly method of the motor assembly line.

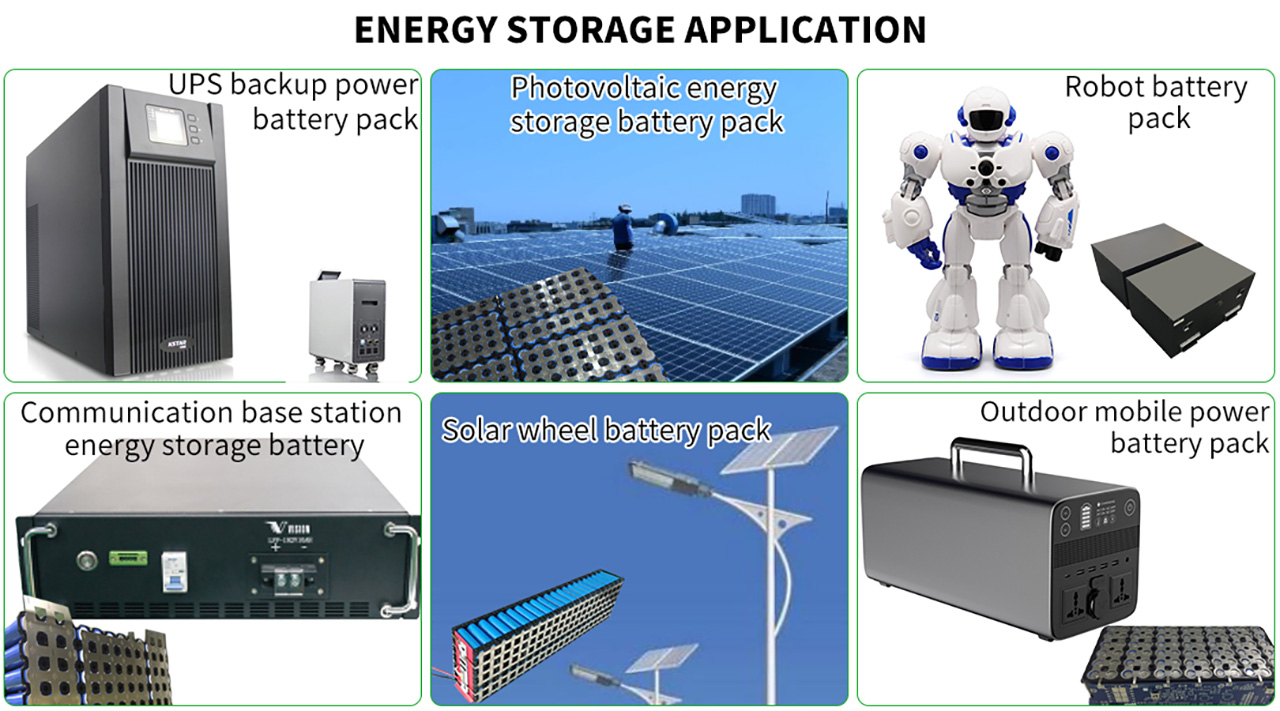

Application Areas

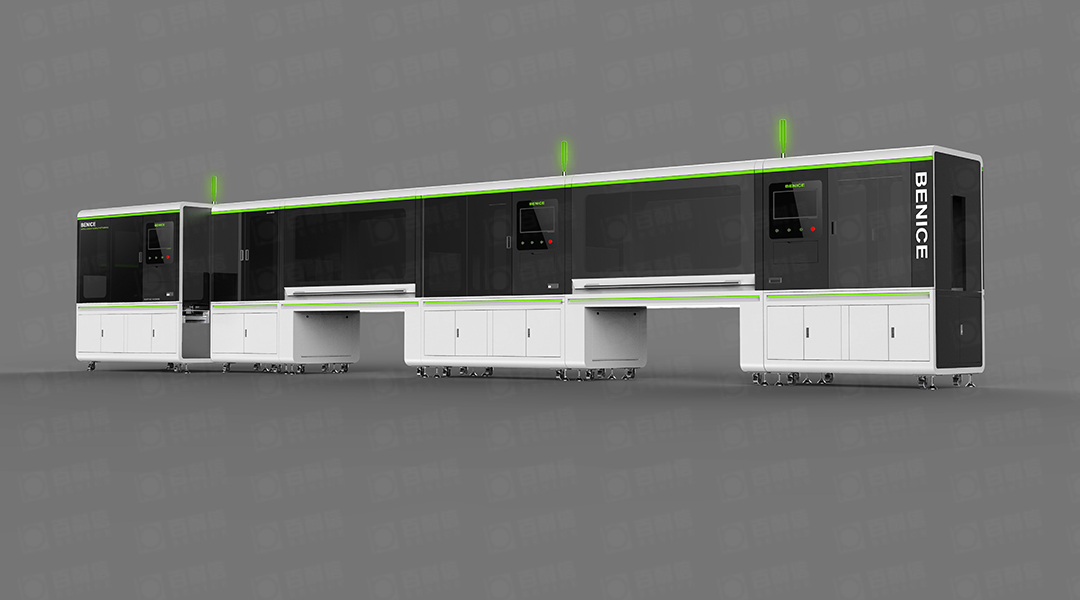

In fact, the motor assembly line is to arrange the disordered motor parts in an automatic orientation that is convenient for saving machine space, and then smoothly transport them to the subsequent escapement to prepare for the subsequent grasping of the manipulator. There will be a testing mechanism in the process of motor composition, which is used to test the components assembled in the previous step or the work results of the machine in the previous step, such as missing parts detection, size detection, defect detection, function detection and material removal detection, and at the same time to achieve defective products. Automatic discharge.

When designing and arranging the motor assembly line, it is necessary to ensure the shortest transportation route of the parts, fast production efficiency, and convenient operation, and also consider the connection between the installation of the motor assembly line. In order to meet these technical requirements, designers need to consider the shape of the production equipment and the arrangement of installation, and the arrangement of the motor assembly line during the installation process should also conform to the motor assembly process.

After-sale service

The installation position of the motor assembly line also involves the degree of connection between the equipment, so it should be sorted according to the assembly position of the mechanical parts. The motor assembly line should also carefully consider the material flow in the overall layout, so as to shorten the route and reduce the transportation workload. In a word, the unit assembly method of the motor assembly line can make the motor products process closely, shorten the circulation time of the motor products in each assembly link, thereby improving the motor production efficiency and product quality.

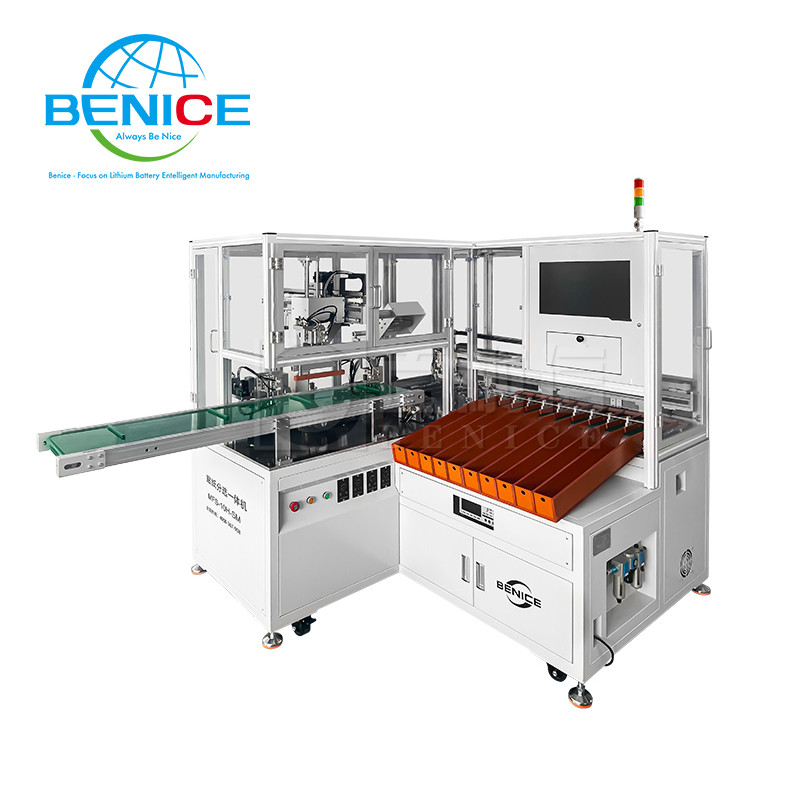

Product detail pictures:

Related Product Guide:

We attempt for excellence, provider the customers", hopes to be the most beneficial cooperation team and dominator enterprise for staff, suppliers and shoppers, realizes value share and continuous advertising for Professional China Internal Resistance Tester Of Battery - Lithium battery assembly automation production line – Benice , The product will supply to all over the world, such as: Estonia, Durban, Munich, We adhere to the honest, efficient, practical win-win running mission and people-oriented business philosophy. Excellent quality, reasonable price and customer satisfaction are always pursued! If you are interested in our products, just try to contact us for more details!

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.